CUSTOMER SNAPSHOT

Client(s): Port of Rotterdam

Client Type: Engineer/Employer

Sector: Port Development

Contractor(s): PowerCon, Heijmans, J.P. van Eesteren

Contract Type(s): FIDIC Yellow Book, UAV, STABU

Project Duration: 2023 – 2025

Project Location: Cruise Terminal, Rotterdam

PHASE

CAPABILITIES

- Risk management

- Contract management

- Process management and SE

Walstroom (Cruise Shore Power Rotterdam)

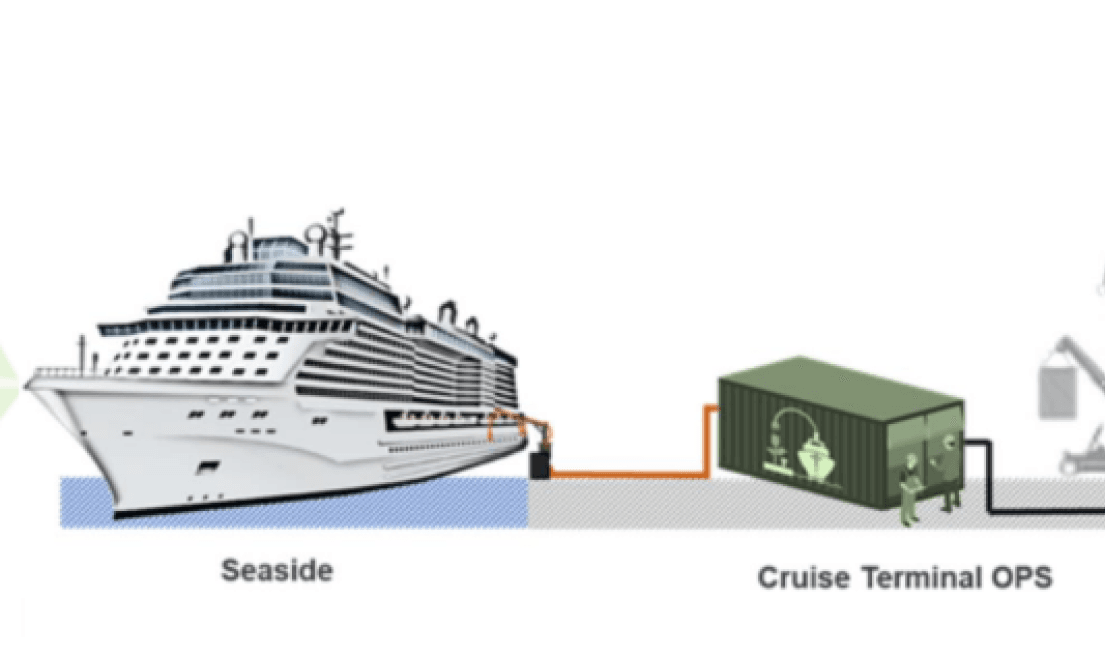

The Shore Power project at Cruise Port Rotterdam is an initiative by the City of Rotterdam, the Port of Rotterdam Authority, and Cruise Port Rotterdam (CPR) to improve the environmental performance of cruise ships visiting the port. The project focuses on making the port more sustainable by providing ships at the quay with electricity from the power grid, known as shore power. This reduces harmful emissions and improves air quality in the surrounding area.

In March 2023, the construction of a shore power installation at the Holland Amerikakade specifically for cruise ships began. This installation will be operational in 2025 and will allow cruise ships to use shore power during their stay in Rotterdam, reducing CO₂ emissions and noise pollution.

The city government aims for all cruise ships visiting Rotterdam to use shore power by 2027, ahead of European regulations that require full shore power connection for cruise ships in European ports by 2030.

Challenge

Solution

Results

With workflows automated and standardized, team members could dedicate their time and energy to critical tasks instead of administrative processes.

Using the pre-defined processes allowed a quick start with faster implementation and reduced setup time.

The use of one system by Employer and Contractors improved the collaboration and real-time information sharing.

Reduced miscommunication and fewer delays in project execution.